New Products

Find LED Pixel Cluster Modules, Arrow Board Parts, C26 LED Pixel Cluster on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

| Payment Type: | T/T,D/P,Paypal,Money Gram,Western Union |

|---|---|

| Incoterm: | EXW |

Model No.: WDM-C26-R/Y/G

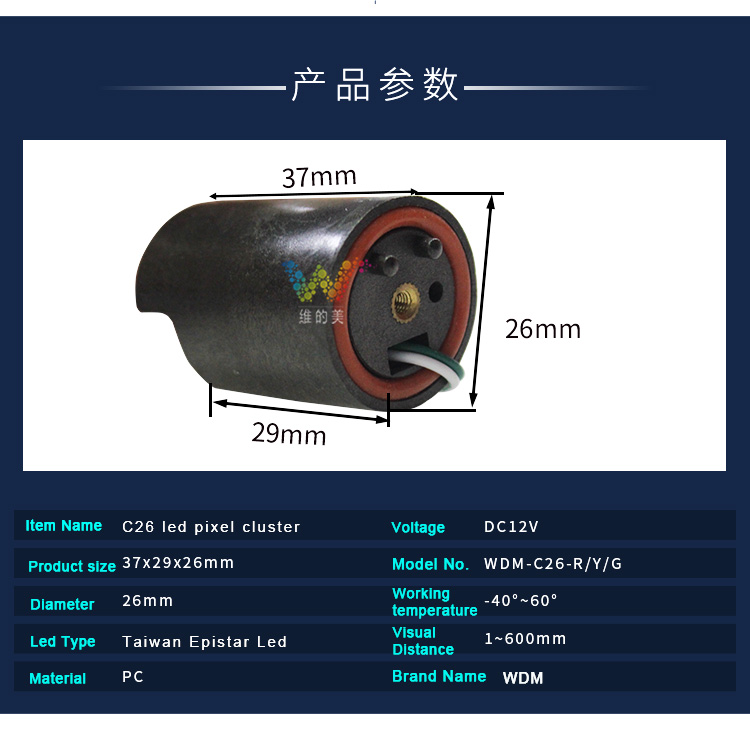

Product parameters for the arrow board parts C26 LED pixel cluster modules:

Product name: C26 pixel tube

Product size: 37 * 29 * 26MM

Model: WDM-C26-R / Y / G

Lamp Bead Color: Red / Yellow / Green

Lamp Bead Type: Taiwan Epistar Chip Lamp

Working voltage: DC12V

Shell material: PC

Working temperature: -40-65 ℃

Life: 100000H

Visual distance: 1-500M

Emitting diameter: 26mm

Brand: Victoria's Beauty

Product production process for the arrow board parts C26 LED pixel cluster modules:

1.C26 pixel tube process flow-pixel tube

The shell of the C26 pixel tube produced by our company has single-pillar and double-pillar housings. There is no difference in appearance. There is only one small pillar at the bottom of the pixel tube and two small pillars at the double-column. As long as it depends on whether the installation position is a column hole or two column holes, you can choose to use a single column or a double column. As shown below.

2.C26 pixel tube process flow-power cord with terminals

Generally, the pixel tubes made by our company use power cables with terminals, which are both beautiful and convenient. You don't need to connect another power cable, you can just plug the terminals on the adapter board. The length of the power cord can be made according to requirements. A card slot is designed on the back of the terminal block to strengthen the connection between the terminal and the adapter board.

3.C26 pixel tube process flow-AI automated production:

Produce the designed circuit board, prepare all the corresponding resistors and LEDs, and then prepare to start the assembly line to start the operation. The AI vertical machine starts to plug in the lights, and the DIP plugs in. Start all the resistors and LEDs. Use a resistor machine to make a resistor on the circuit board, and then put it into the universal vertical machine to start LED direct plug-in. According to the set procedure, insert the entire LED board.

4.C26 pixel tube process flow-quality inspection

All the lamp boards with resistance and LED completed are inspected by the company's quality management. After there are no problems, this product enters wave soldering, and then all LED pin tubes are completely welded. The wave soldering points are fuller and the solder is uniform. Does not solder; and uses environmentally friendly lead-free tin.

After soldering the C26 lamp board, you can start working on the assembly line. All accessories, such as power cords, pixel tube housings, auxiliary tools, etc. are ready; start division of labor and cooperation, first pass the power cord with terminals through the pixel tube. The shell is then soldered to the soldered C26 lamp board, and then white glue is applied to the power cord and the tin point of the lamp board to prevent oxidation; remove the lamp board according to the pattern on the lamp board, and then put the lamp board into the pixel tube Inside and flatten, fix the pixel tube with iron plate, so that the machine can fill the glue.

5.C26 pixel tube process flow-mechanical glue:

The glue is filled by a fully automatic glue machine. After the AB component glue is combined, it is filled and sealed according to a ratio of 10: 1. It is best not to lower or increase the ratio. He can dry in about two hours, and completely dry in about 4 ~ 6 hours. This glue will provide a good guarantee for long-term use.

After the pixel tube is filled with glue, the pixel tube is placed on a horizontal plane, and it is required to test with a level meter, and then each pixel tube is as flat as possible, and the horizontal positions of the four corners are on the same horizontal plane. It is also very important. The selection of AB glue must use more than 40 yuan per kilogram of glue. His adhesiveness and durability will be very good. It cannot be filled with sub-filled glue. It will crack after a long time. Pixels Water will leak inside the tube.

After the pixel tube is dry, you can organize all the pixel tubes and start packaging. Generally, firstly use a transparent sealed bag to pack 50 bags, and put a label on the bag. The label indicates the product name and working voltage. , Product quantity, etc.

application:

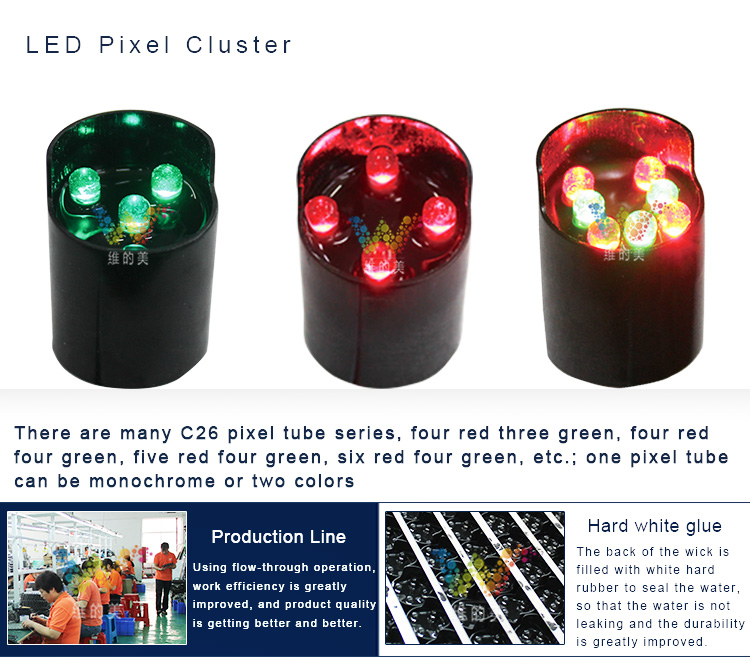

The pixel tube is a type that can be freely arranged and combined into various texts or patterns, with small size and exquisite appearance. It is mainly used in highways, toll stations, parking lots, etc. There are many C26 pixel tube series, four red, three green, four red and four. Green, five red, four green, six red, four green, etc .; one pixel tube can be single color or dual color can be used.

Product Application Cases:

Product Categories : Outdoor Led Display > Led Pixel cluster